Individually manufactured silicone orthosis is comfortable to wear, fits well and helps correct misalignment.

Case example

The misalignment of the big toe (hallux valgus) and reduced sensation in the foot caused severe rubbing between the toes of a diabetic patient, resulting in skin problems.

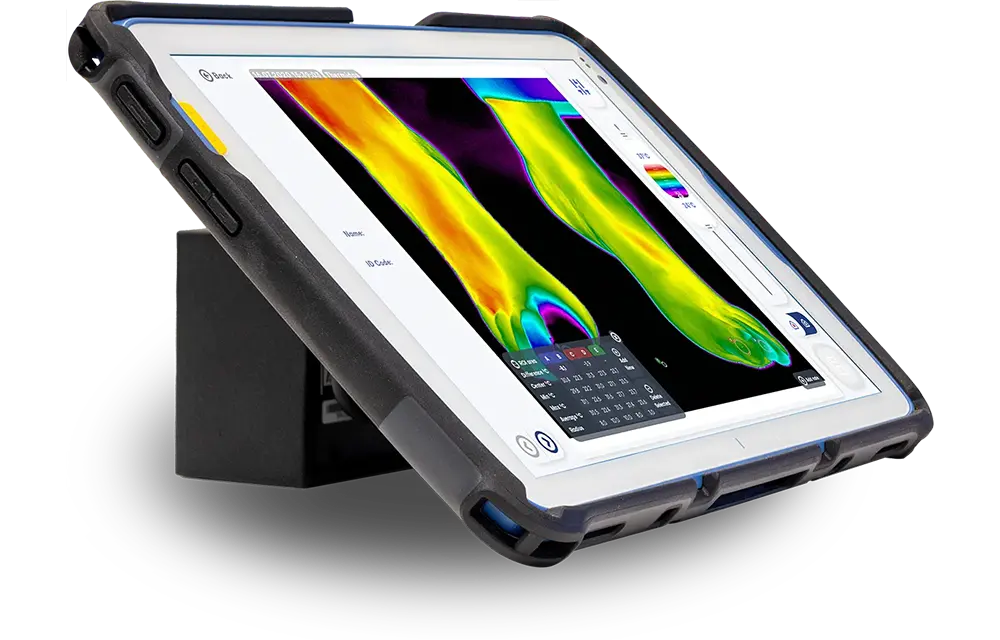

Pia Kallio, a podiatrist, decided to make a custom silicone orthosis for the client. Kallio actively used thermal imaging to confirm the fit of the orthosis. The first version of the orthosis reduced blood flow to the toes, after which it was modified.

After modification, the patient used the orthosis regularly when moving around. The problems caused by rubbing were reduced, the calluses started to heal and the position of the toes was corrected.

Follow-up thermograms were taken of the patient’s feet and they indicated that the blood flow to the toes was impaired. The orthosis was again further modified and the instructions for use were changed.

The patient would wear the orthosis mainly only when moving, and on less active days, the orthosis would not be worn.

Thermal imaging was actively used in the orthosis-making process, helping to optimize the design and provide individualized and practical guidance in the use of the orthosis.